Services

Past Projects

We have been involved in a long list of very interesting projects over the years, and as you can imagine, a lot of these projects were performed under strict Non-Disclosure agreements. This means that as much as we would like to share pictures, videos and explanations, we are simply not able to do so.

Some projects we are able to talk about when we are under NDA with you too, and some things we can show when you visit our facility, but can not share in emails or on a website.

Get in touch so we can better explain what our true capabilities are.

The following section is an Anchor Point. The text is left invisible but it allows linking from the Home page.

DO NOT DELETE!

Engineering and Design top anchor

Engineering and Design

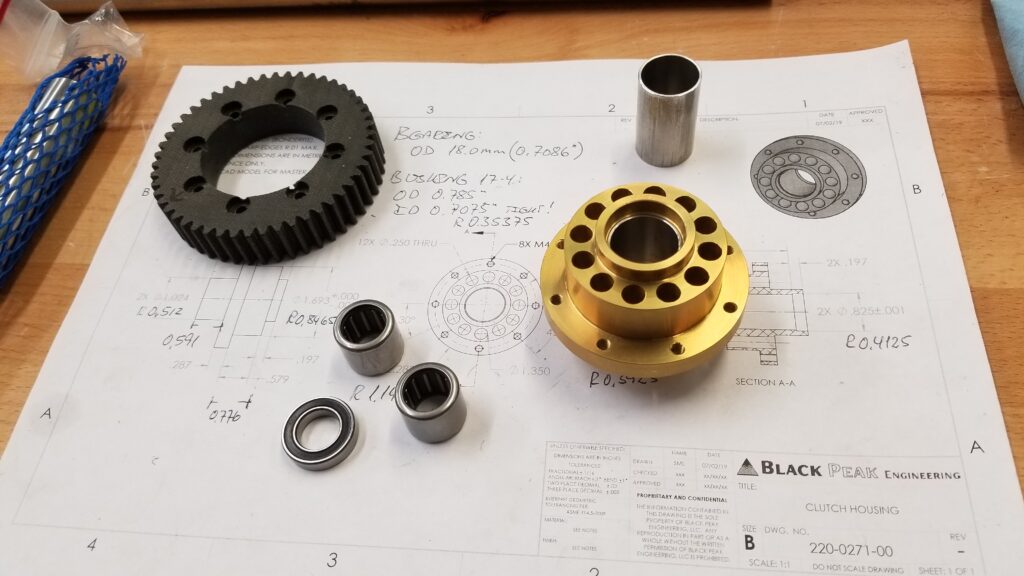

- Mechanical Design

- Individual parts to advanced assemblies and complete systems.

- Reverse engineering and documentation

- SolidWorks, CATIA, Fusion360

- Electrical Design

- Avionics systems, Wire harnesses, Automotive systems etc.

- UAS Systems Integration

- UAS Payload Integration

- Electronics Design

- Digital and Analog systems

- Circuit board layout and Assembly

- Composite Part and Mold design

- Individual parts and whole Assemblies.

We will take your idea from a Napkin sketch, or something as simple as a verbal description of the concept, to a final product. Together we will go through Conceptual Design, Preliminary Design and finally get to a Detail Design that captures your product idea.

We can then go on to the fabrication of prototypes and testing.

The following section is an Anchor Point. The text is left invisible but it allows linking from the Home page.

DO NOT DELETE!

Prototype_Fabrication_top_anchor

Prototype Fabrication

- CNC machining of parts, welding, bending etc.

- Composite part fabrication and assembly of composite parts and other mechanical parts.

- Simple or Complex assemblies.

- Wiring and Cable harnesses

- Circuit board population, incl high density SMD components

- Electronic and Electric assemblies

The process of fabricating a prototype can be a simple as machining a few parts, or as complicated as building a complex device consisting of hundreds of individual parts. At Black Peak Engineering, we have the tools and knowledge to go all the way to an advanced device with as much complication as is needed. We have a machine shop, a composite shop, and an electronics shop, so any required component or assembly can be made in-house. This also allows us to quickly design and fabricate revised components, if the testing shows a design review is needed.

The following section is an Anchor Point. The text is left invisible but it allows linking from the Home page.

DO NOT DELETE!

Test_and_Validation_top_anchor

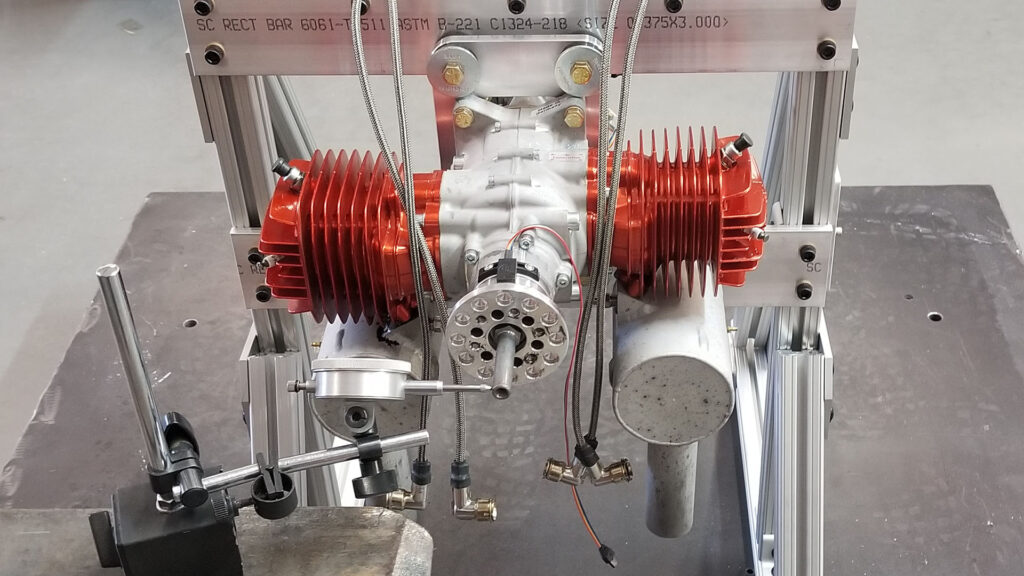

Test and Validation

- Design and build of test setups

- Jigs and Fixtures

- Development of test plans and test cards

- Perform testing of individual components or complete systems

- Perform or assist with ground and flight testing of UAS

- Engine testing, piston and turbine engines

- Propeller and Rotor blade testing

- Generate test reports

All development requires testing to either verify the original design expectations, or optimize the design for the best possible performance. Black Peak Engineering has extensive experience that allows us to build up any required test jigs and fixtures, outfit the test system with a range of sensors, and set up electronics systems to collect data from the test system. Finally, we set up a computer based data collection and visualization system which allows us to study the collected data in relation to other data, and in many cases to recorded video and sound. All of this is tremendously useful during the performance validation and optimization phases of any project.

Fabrication

CNC machining

Turning

Bending: Tube and Sheet

Welding

3D Printing

Surface Treatment

Assembly

Composite parts

Composite assemblies

Unmanned Systems

Air, Ground, Surface, and Sub-Surface systems

Autopilot integration

Avionics integration

C2 and Video system

Payload integration

Ground Control station

Support Equipment

Electronics

Design of electronic circuits, Digital and Analog.

Design of printed circuit boards.

Population of circuit boards, by hand

Firmware development

System test

Composites

Composite Part design

Plug and Mold design

Plug and Mold machining

Composite part fabrication, “Out of Autoclave”

Composite part finishing and assembly